Powder coating auto wheels offers several benefits that make it a popular choice among vehicle owners.

Here are some compelling reasons why someone might choose to powder coat their auto wheels:

Durability: Powder coating creates a tough, resilient finish that is highly resistant to chipping, scratching, and corrosion. This makes it ideal for protecting wheels from the wear and tear they experience on the road.

Longevity: Powder-coated wheels have a longer lifespan compared to traditional paint or other finishes. They can withstand exposure to harsh weather conditions and road chemicals without deteriorating.

Aesthetic Appeal: Powder coating offers a wide range of color options and finishes, allowing vehicle owners to customize the appearance of their wheels to match their personal style and the overall look of their vehicle.

UV Resistance: Powder-coated finishes are resistant to fading and damage from UV rays, ensuring that your wheels maintain their vibrant color and appearance over time.

Environmental Friendliness: Powder coating is an environmentally friendly process that produces minimal waste and does not emit harmful solvents or VOCs (Volatile Organic Compounds).

Easy Maintenance: Powder-coated wheels are easy to clean and maintain. They can be wiped clean with mild soap and water, and the finish remains intact.

Cost-Effective: While the initial cost of powder coating may be slightly higher than some other finishing options, the long-term savings in terms of reduced maintenance and replacement costs can make it a cost-effective choice.

Uniform Finish: Powder coating provides a uniform, consistent finish with no drips, streaks, or brush marks, ensuring a polished and professional look.

Versatility: Powder coating can be used on a variety of wheel materials, including aluminum and steel, making it a versatile choice for different types of wheels.

Resale Value: Well-maintained, powder-coated wheels can enhance the overall appearance of a vehicle, potentially increasing its resale value.

Powder coating wheels is a multi-step process that requires careful preparation and attention to detail.

Here are the general steps involved in powder coating wheels:

Wheel Removal:

Remove the wheels from the vehicle and ensure they are clean and free of any dirt, grease, or debris. This step is crucial to achieve a smooth and durable finish.

Tire Removal (Optional):

If you want to completely coat the wheel, consider removing the tires from the rims. This is not always necessary, but it allows for a more thorough coating.

Cleaning:

Thoroughly clean the wheels using a degreaser or a wheel cleaner to remove any contaminants. Rinse them with water and allow them to dry completely.

Surface Preparation:

To create a good surface for the powder coating to adhere to, you may need to sandblast or media blast the wheels. This step removes any existing paint, rust, or old coatings and creates a clean, roughened surface for the powder to bond with.

Masking (Optional):

If you want to protect certain areas of the wheels, such as the wheel hubs or lug nut holes, you can apply masking tape or plugs to cover these areas.

Preheating:

Preheat the wheels in an oven to a temperature typically between 350°F to 450°F (175°C to 230°C). This helps to eliminate moisture and contaminants, ensuring a smooth and even coating.

Powder Application:

Apply the electrostatically charged powder coating material to the preheated wheels using a powder coating gun. The positively charged powder particles adhere to the grounded metal surface.

Curing:

Transfer the coated wheels to an oven and bake them at a specific temperature for a set amount of time. The curing process typically takes around 15 to 30 minutes at temperatures ranging from 350°F to 450°F (175°C to 230°C). This process melts the powder, allowing it to flow and form a smooth, durable finish.

Cooling:

After curing, allow the wheels to cool down to room temperature. This helps to solidify the powder coating and ensures it hardens properly.

Inspection:

Carefully inspect the coated wheels for any imperfections, such as runs, sags, or inconsistencies in the finish. If necessary, you can perform touch-up work at this stage.

Reassembly:

If you removed the tires, reassemble the wheels and tires. Ensure that lug nuts are tightened to the manufacturer's specifications.

Quality Assurance:

Perform a final inspection to ensure the coating is even, durable, and meets your desired finish standards.

The specific details and equipment required may vary depending on the size and complexity of the wheels and the equipment available to you. It's essential to follow safety precautions and use appropriate protective gear when handling chemicals, powders, and high-temperature processes during powder coating.

Additionally, always refer to the manufacturer's guidelines for the specific powder coating materials and equipment you are using.

Custom Painting

Choosing "The Dip Doctor" for Custom Painting Your Wheels offers several compelling reasons:

Experience:

The Dip Doctor. has been in the vehicle and wheel business for over 25 years, longer than many other providers. This extensive experience translates into a deep understanding of wheels and a proven track record of quality workmanship.

Innovative Services:

The Dip Doctor is known for introducing the "SAME DAY RIM REPAIR" service in the late 1990s, showcasing a commitment to innovation and meeting customer needs promptly.

Specialization:

The Dip Doctor specializes in custom and specialty finishes for wheels. This specialization ensures that their team is highly skilled and knowledgeable in the art of wheel customization.

Cutting-Edge Technology:

The Dip Doctor. offers cutting-edge technology such as Powder Coating, which combines eco-friendly pre-treatment with improved application techniques and pulse power technology. This results in a durable and high-quality finish.

Patented Process:

Their patented Fusion Coating process sets them apart from competitors, demonstrating their dedication to providing unique and exceptional services.

Quality Assurance:

The Dip Doctor is committed to delivering top-notch quality. Their extensive experience, innovative services, and use of advanced technology contribute to ensuring that your custom-painted wheels meet or exceed your expectations.

Customization Options:

With The Dip Doctor, you have a wide range of customization options, including various colors and specialty finishes, allowing you to create a unique and personalized look for your wheels.

Timely Service:

The introduction of the "SAME DAY RIM REPAIR" service underscores their commitment to providing efficient and timely service, minimizing downtime for your vehicle.

Reputation:

The Dip Doctor has built a strong reputation in the industry for their quality work and innovation. You can trust that your wheels are in capable hands.

Customer Satisfaction:

Ultimately, The Dip Doctor prioritizes customer satisfaction. Their years of experience, innovative services, and commitment to excellence are all aimed at ensuring you are delighted with the results of your custom-painted wheels.

In summary, My Wheel Dr. combines a wealth of experience, innovation, advanced technology, and a commitment to quality to make them a compelling choice for anyone seeking custom painting services for their wheels.

About Us

Since its establishment in 1996, The Dip Doctor. has risen to become the leading supplier of custom and specialty finishes in the industry. With over 25 years of experience in the vehicle and wheel sector, we hold a longer tenure under the same ownership than any other company. Our contributions have played a significant role in advancing modern innovations within Houston's wheel and tire industry. In fact, it was MWR that first introduced the "SAME DAY RIM REPAIR" service in the late 1990s. These innovations are deeply ingrained in our identity.

Today, we are thrilled to present Powder Coating, an advanced powder coating technology that combines eco-friendly clean pre-treatment with enhanced application techniques and pulse power technology. Fusion Coating is a patented process that sets us apart in the industry.

Get In Touch

Email: [email protected]

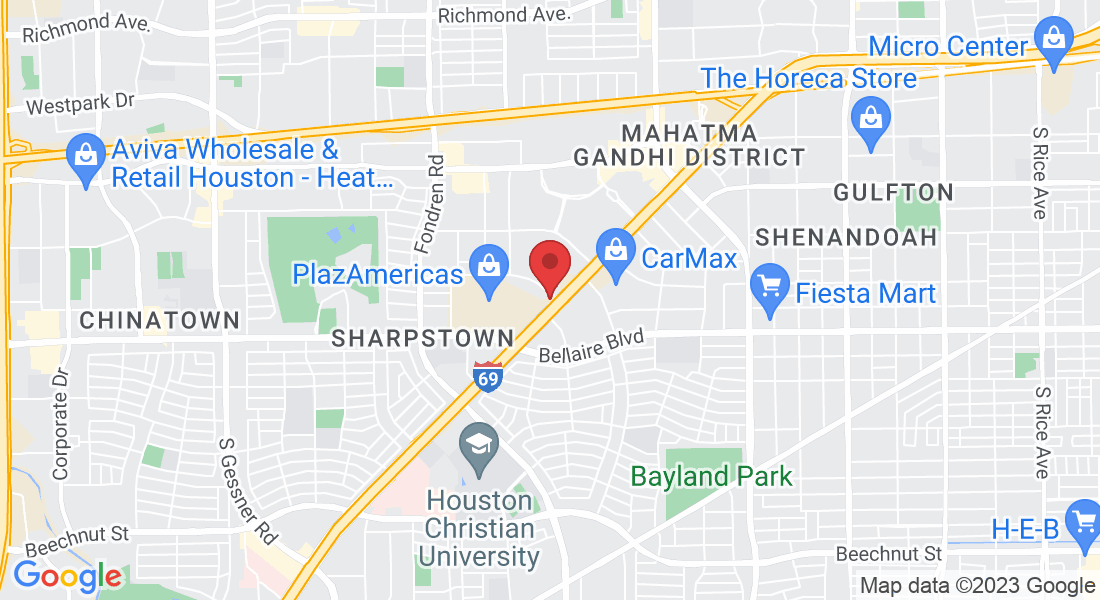

Address

Office: 7070 Southwest Freeway Houston TX 77074

Assistance Hours

Mon – Sat 9:00am – 8:00pm

Sunday – CLOSED